The machine has been designed for separation of liftings and dust from cereals. It is used in cleaning section of flour mills or, if the case maybe, in intake routes of grain silos for grain precleaning.

It is installed as a separate piece of equipment or as an end element lined with screen grader Ariel 60 / separator or the scouring machine Atlas.

The machine separates liftings and dust in a closed space by means of circulated stream of air.

- Energy-Saving Equipment

- Compact and space-saving design

- Low cost of installation

- Reduced filtration area requirement

- Minimal vacuum in the working hall

- Low maintenance and service costs

From the inlet (1) grain comes to the feeder (2) suspended on springsto be distributed to the entire width of the machine case. The grain curtain is aerated by air from the fan (8) and lifted into the vertical aspiration channel (3) where dust and liftings are separated from grain. Clean grain is discharged via the outlet (7) with a counterweighted flap for the next process. Liftings are separated from the air stream in the separation chamber (4) and by the worm (5) and then via air lock (6) it is removed from the machine. Air, free from liftings, is sucked in by the radial fan (8) and via bypass channel returned back to the aspiration channel to be used again.

Air sifting conditions, i.e. intensity of cleaning, are controlled by variable width of the channel and inclination of its wall. With the Asana 3 model used in connection with the screen grader/separator, where processed material has already been spread within desired width, there is a built-in permanent magnet separator mounted instead of the feeder.

| Type | Max Output (t/h) | Power Input (kW) | Aspiration Air Volume (m³/min) | Net Weight (kg) | Built-Up Space (m³) |

|---|---|---|---|---|---|

| ASANA 10 | 10 | 2.2 + 0.55 | 4 | 339 | 2.7 |

| ASANA 15 | 15 | 4.0 + 0.55 | 6 | 428 | 3.7 |

| ASANA 15M | 15 | 4.0 + 0.55 | 6 | 410 | 3.7 |

Note: Power supply: 415V, 50Hz. Capacity may vary based on grain type, moisture, and contamination.

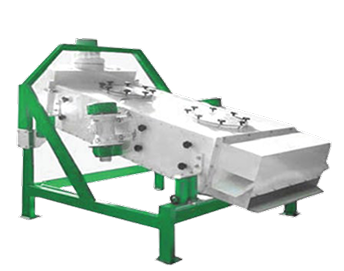

ASANA 10

Self-standing machine with 600mm width, built-in feeder, and Ø100mm socket. Suitable for standalone use or with a scouring machine.

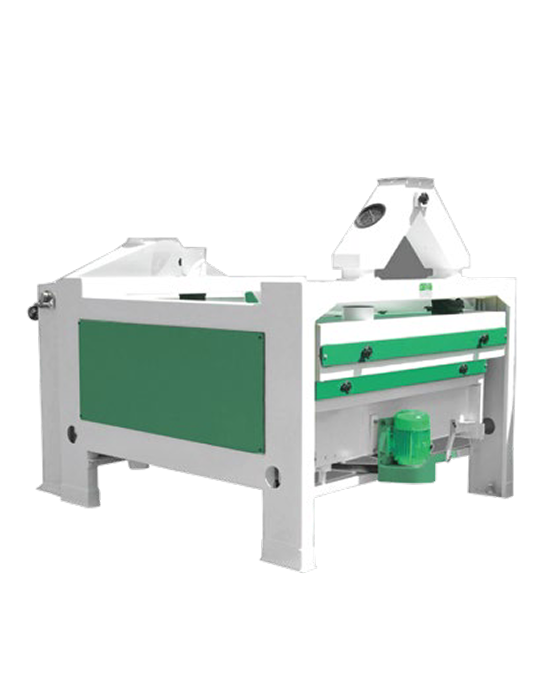

ASANA 15

Self-standing 995mm wide machine with built-in feeder. Suitable for both independent operation and integration with scouring equipment.

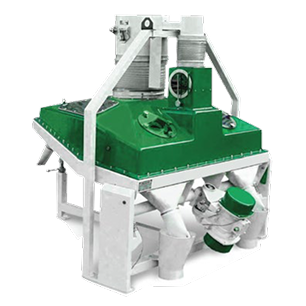

ASANA 15M

Used with screen grader Ariel 60. 995mm width. Inlet adaptable to grader outlet. Features plate magnet separator instead of feeder.

Note: Up to 10% air renewal is required via the aspiration socket. Additional inlet sockets available as needed.

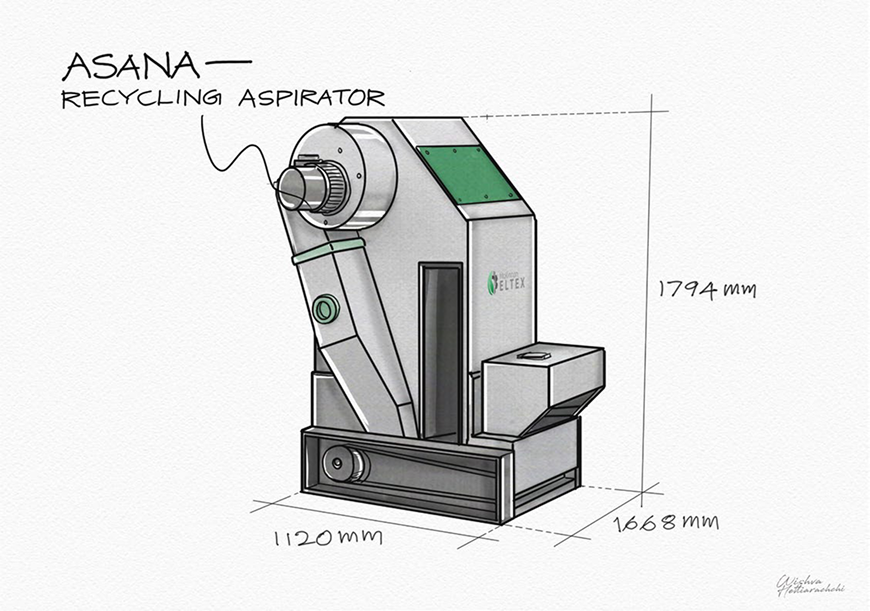

Height: 1794 mm

Width: 1120 mm

Length: 1668 mm